With endless demand for speed and efficiency in the construction process, and Singapore’s buildings growing taller and faster, the Singapore government is challenging local construction companies to adopt more automated and digital processes through initiatives, such as a joint announcement from the BCA and IMDA to encourage the adoption of robotics and automation.

One area that is ripe for gains in automation and robotics is the construction of lift shafts, an infamously time-consuming process. World-leading lift and escalator manufacturer, Schindler, has created the perfect solution: Schindler R.I.S.E, which arrived in Singapore in April to work on the redevelopment of the iconic Shaw Tower located on Beach Road.

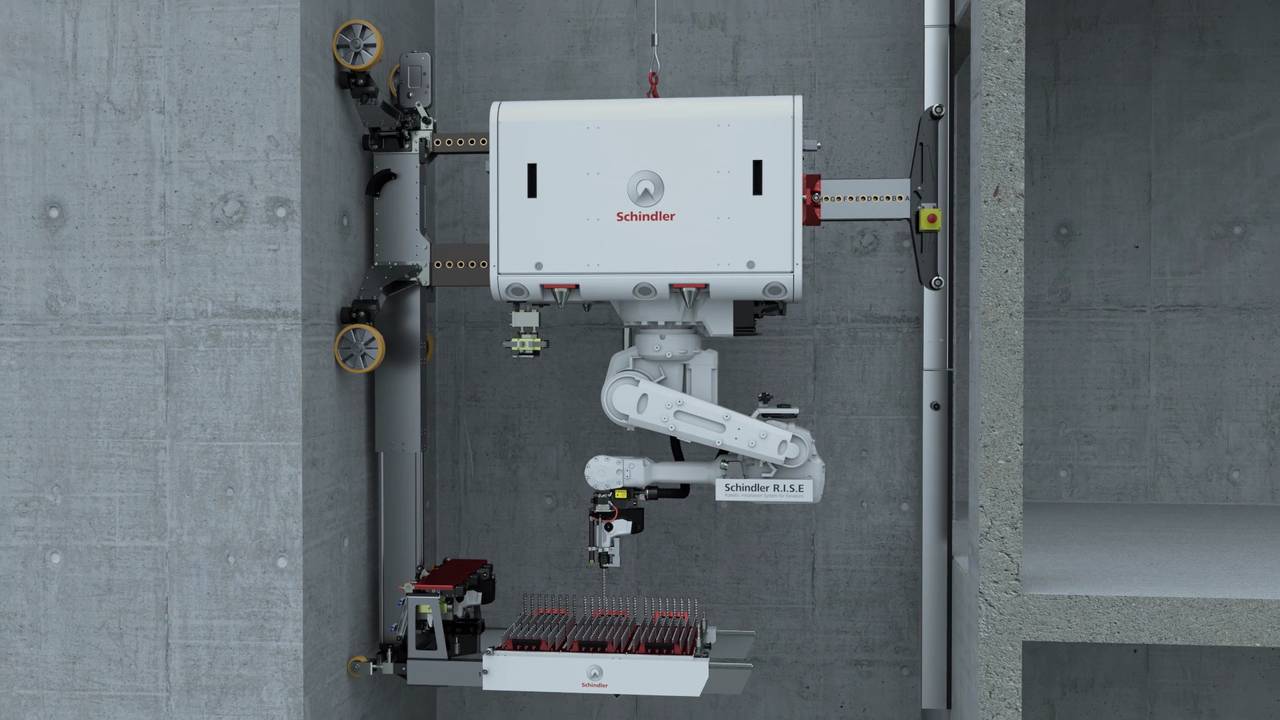

Schindler R.I.S.E is the world’s first self-climbing robot that is designed to manoeuvre itself along the building’s elevator shaft to install components. It is equipped with tools to drill holes and install anchor bolts with precision and speed.

Traditionally, this part of the construction process is undertaken by construction professionals. However, it is gruelling and time-consuming work. With Schindler R.I.S.E, human involvement in this part of construction is limited to a specialist operator who monitors the robot’s movements via a remote-control panel. This not only speeds up work, but [also] reduces the risks of errors, rework, or accidents.

“Schindler has around 70,000 employees globally, and each day, two billion people travel in one of our elevators for an average of 30 seconds. Our commitment is to ensure the safety and well-being of every one of them. It is through pioneering innovations, such as Schindler R.I.S.E, that we fulfil this promise,” said Michael Li, Managing Director of Schindler Lifts Singapore.

Schindler R.I.S.E completed its task on the new Shaw Tower in June. This 200-metre, mixed-use tower will boost the ongoing rejuvenation of Singapore’s Downtown Core. With leading credentials, Shaw Tower features technology-enabled features for a scalable and sustainable workplace.

“We are thrilled that Schindler has deployed R.I.S.E. for Shaw Tower,” said Alfred Yeung, General Manager of building owner Shaw Towers Realty. “With its speed and accuracy, we achieved time savings and improved safety outcomes compared to conventional installation methods. This also aligns with our corporate philosophy to use technology for better and more efficient solutions—for the construction of the tower now, and more importantly, for building users of Shaw Tower in the future.”

Schindler R.I.S.E is the first construction robot of its kind, and uses advanced automated technology to deliver the fastest elevator installation method seen to date. The robot can execute a series of previously manual steps with ultimate precision and autonomously.

“Safety is our top priority, and the use of Schindler R.I.S.E. is an example of initiatives that we support to improve safety on projects like Shaw Tower—working safer and smarter,” said Ben Hobbins, Senior Construction Manager of Lendlease, which is managing the development, project management and construction, and operations of the building on behalf of Shaw Towers Realty.

There are currently five robots in existence, which traverse the world supporting new construction projects. The technology continues to feature great success on projects across Europe, Asia, and the Middle East. It has the potential to change how building contractors approach the process of installing the lift shaft. With the Council for Tall Buildings and Urban Habitats marking Singapore in the top twenty tallest cities, the performance of Schindler R.I.S.E will be keenly monitored.

See a video of Schindler R.I.S.E on the Shaw Tower project here, or learn more about the robot here.